ABOUT MY SHARPENING SERVICE

With more than 30 years' experience, I am committed to providing a sharpening service of the highest quality, paying particular attention to the finest detail and working efficiently while keeping the lines of communication with my clients clear and concise. My priorities are simple - they're yours!

My mission at Sharp Again is simple: to provide high-quality sharpening services in a timely manner. I cater to each project’s specific needs to ensure excellence. Your blades and tools receive a spa-like treatment and will come home refreshed and rejuvenated.

To book an appointment or for more information, feel free to call or email today!

SHARP AGAIN

Artisan Blade Sharpening Service

"There's never a dull moment!"

SHARPENING PROCESS

THE SHARP AGAIN PROCESS

I typically use a 4 step sharpening process:

The first step is to repair any defects in the knife, such as a broken tip, chipped edge, reverse bow or high bolster. Once the necessary repairs have been completed, the blade is thinned by creating a proper relief angle, or primary bevel. Minimum metal is removed.

The second step is to further refine the relief angle.

The third step is to apply the secondary bevel, or cutting edge.

The fourth and final step is to remove the burr (wire edge) and polish the cutting edge.

In the case of serrated knives, if the serrations are in good shape I will sharpen the reverse side. If the serrations are badly worn, the knife will re-serrated manually, one scallop at a time.

SHARPENING TECHNIQUE

My process and technique depends on the type of knife I’m sharpening. The majority of knives I give a polished yet slightly toothy edge; one that can both slice and shear in the same cut. I am a proponent of the convex edge, it can give the cutting edge extra support under stress and touches up quickly (depending on the blade steel).

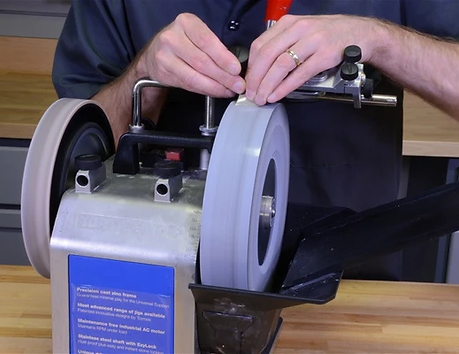

The tools I use are variable speed and water cooled to ensure the temper isn’t taken out of the knife, essentially “burning” the blade.

Traditional, hand made Japanese knives are sharpened exclusively on water stones. My typical stone progression starts at 400 grit, a few passes on the 1000 to decrease the scratch pattern created by the 400, then some quality time on a 3000, and finishing passes on my 8000. Then I finish strop with 0.5 micron (60,000 grit) diamond emulsion.

The result is the strongest, sharpest, longest-lasting and most easily maintained edge available!